Horizontal centrifugal pumps

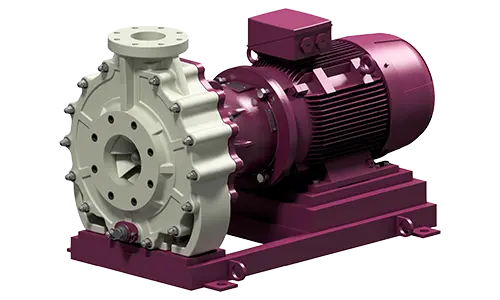

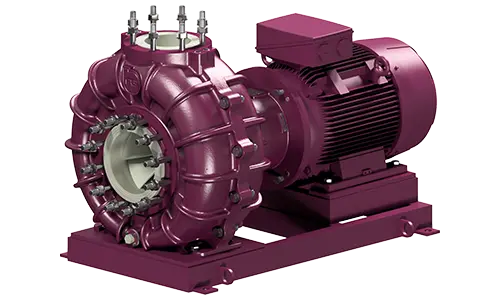

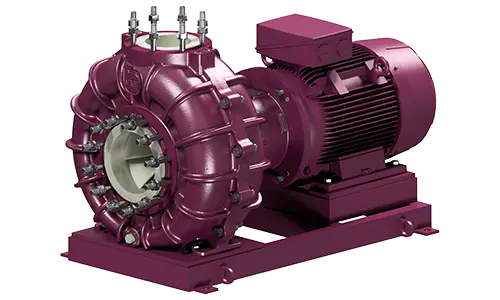

CMO-Q

HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

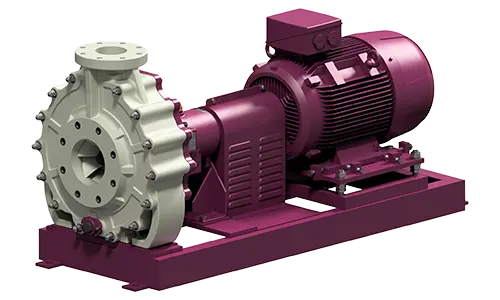

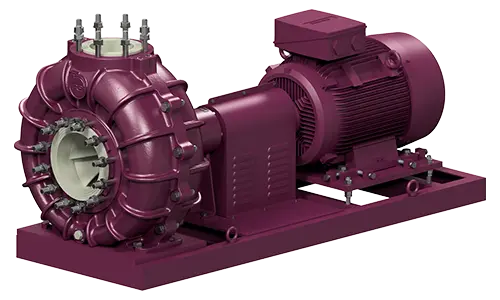

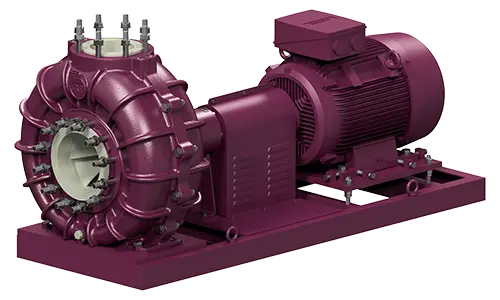

CMO-N

HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

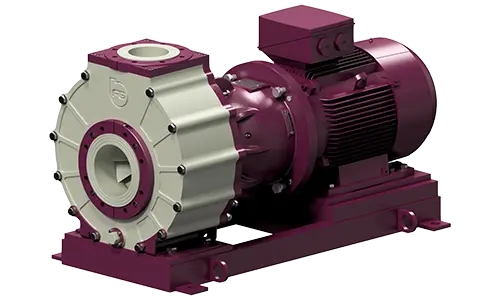

CDI-QL

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

- LIBRA -

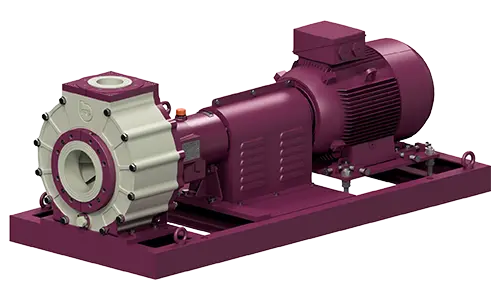

CGI-L

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

LONG COUPLED

- LIBRA -

CDI-QS

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

- SCORPIO -

CGI-S

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

LONG COUPLED

- SCORPIO -

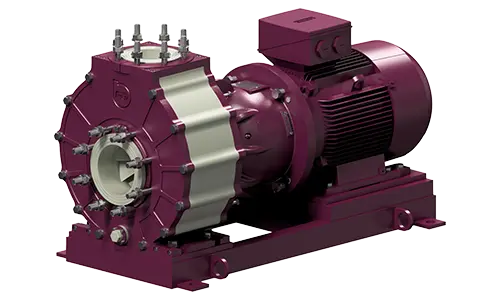

CDI-QT

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

- TAURUS -

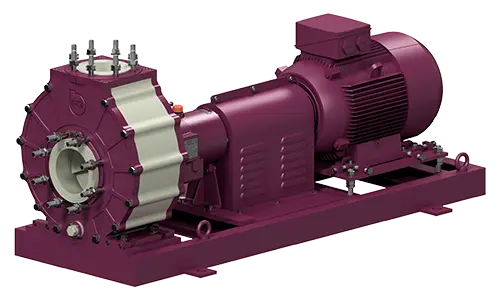

CGI-T

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

LONG COUPLED

- TAURUS -

CDA-QL

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

- LIBRA -

CGA-L

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

LONG COUPLED

- LIBRA -

CDA-QS

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

- SCORPIO -

CGA-S

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

LONG COUPLED

- SCORPIO -

CDA-QT

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

- TAURUS -

CGA-T

NORMALIZED HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

LONG COUPLED

- TAURUS -

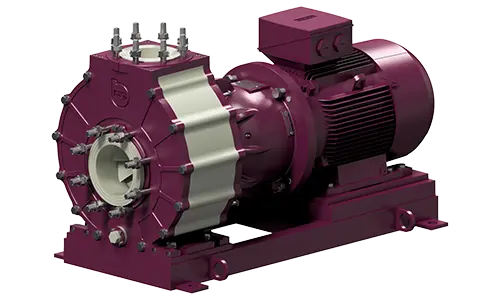

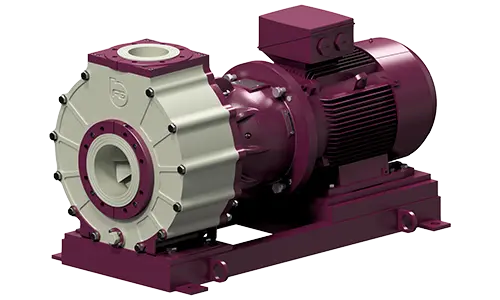

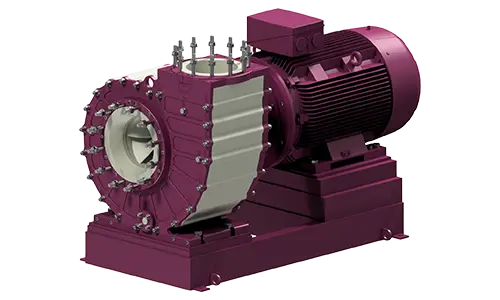

CMK-Q

HIGH FLOW

HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

CLOSE COUPLED

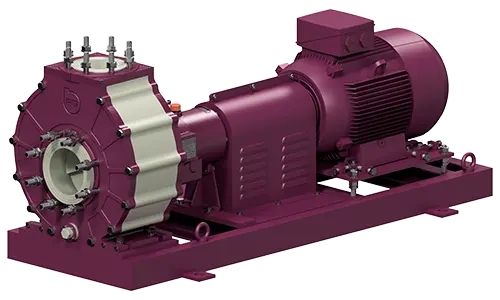

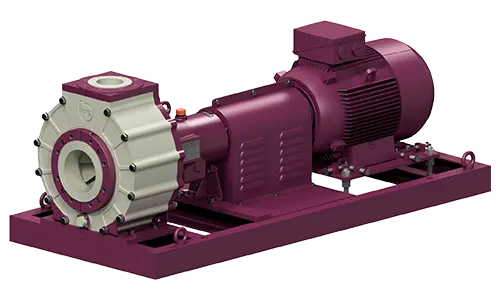

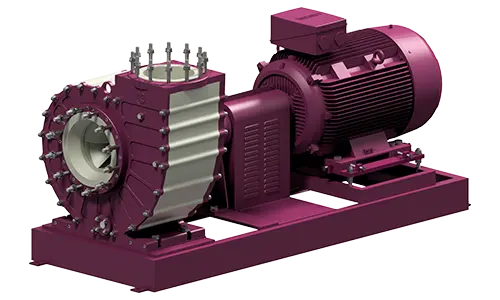

CGK

HIGH FLOW

HORIZONTAL CENTRIFUGAL PUMPS WITH MECHANICAL SEAL

LONG COUPLED