Home » Vertical centrifugal pumps » CFV-N

CFV-N

Fiberglass centrifugal sump pumps

LONG COUPLED

The Vitrum line was developed for mildly to severely corrosive liquids and able to withstand arduous working condition. All wetted parts are in reinforced fiberglass material, in order to resist abrasion and severe temperatures between -45°C (-50°F) and 120°C (250°F).

The vertical centrifugal with coupling range CFV-N, has been designed in order to obtain the best performances and a total reliability. Easy to handle, the pumps of this range are strong, compact construction, produced in their components with high thickness to give a product with the maximum strength.

Material of Construction

The materials in contact with the pumped liquid are thermoplastic (PP-PVDF-PEHD); the column length is available from 500 to 5000 mm.

Accessories

• Motor rain guard

• Filter on suction line

• Extension pipe on suction line

RTM molding

The fiberglass components of the CFV-N pumps are obtained by RTM (RESIN TRANSFER MOULDING) using vinyl ester reinforced with long glass-fibers.

Download the catalog and the technical sheet complete with technical drawing with overall dimensions

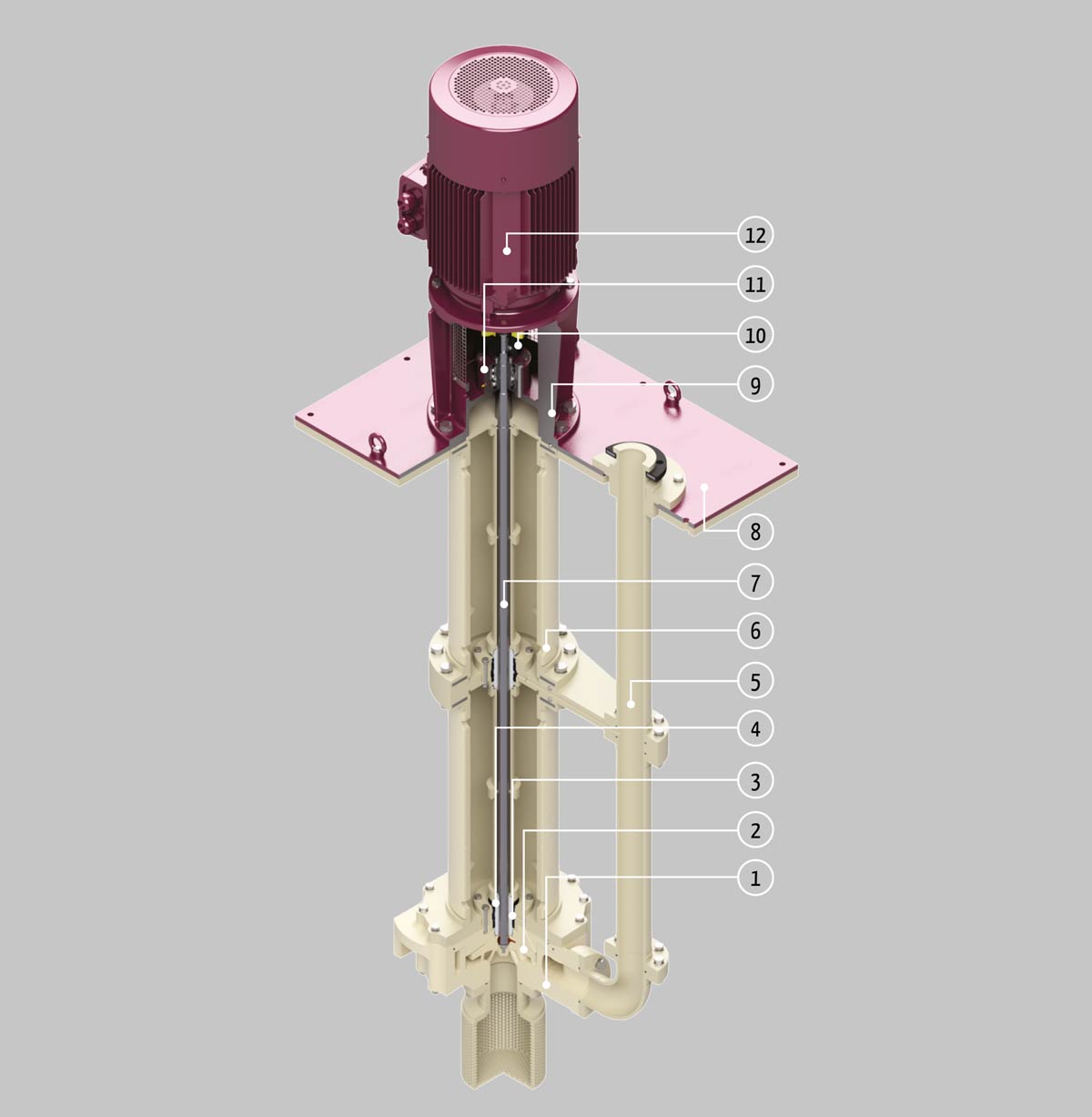

Main Components

Pump casing made in solid FRP with high thickness to ensure optimal mechanical strength and chemical resistance.

Semi-open centrifugal impeller with rear back-vanes for axial self-balancing; with encapsulated metallic insert.

Static guide bushing in PTFE CG (SiC available on request).

Rotating guide bushing in Al2O3 (SiC available on request).

Thermoplastic discharge pipe.

Column manufactured from thermoplastic material reinforced in FRP material.

Balanced shaft made of SS316 Stainless steel or 42CrMo4 Carbon steel, structured to easily support torsional and radial forces. Made exclusively from solid bar stock using mechanical machining processes and fully coated in thermoplastic material. Axial shaft adjustment system, in order to permit the impeller approaching to the casing in case of partial blades consumption and to restore the initial pump performance.

Extra-thick PP plate reinforced with a sheet of steel.

Intermediate adaptor in cast iron contains the support for the bearings and the elastic coupling and distances the motor from the rest of the pump.

Elastic coupling fitted to absorb any axial misalignment and allow the motor to be disassembled without having to remove the pump.

Steel support houses two ball bearings that guide the shaft.

Three-phase asynchronous electric motor, in compliance with IEC (NEMA available on request).

application sectors