Home » Horizontal centrifugal pumps » CGK

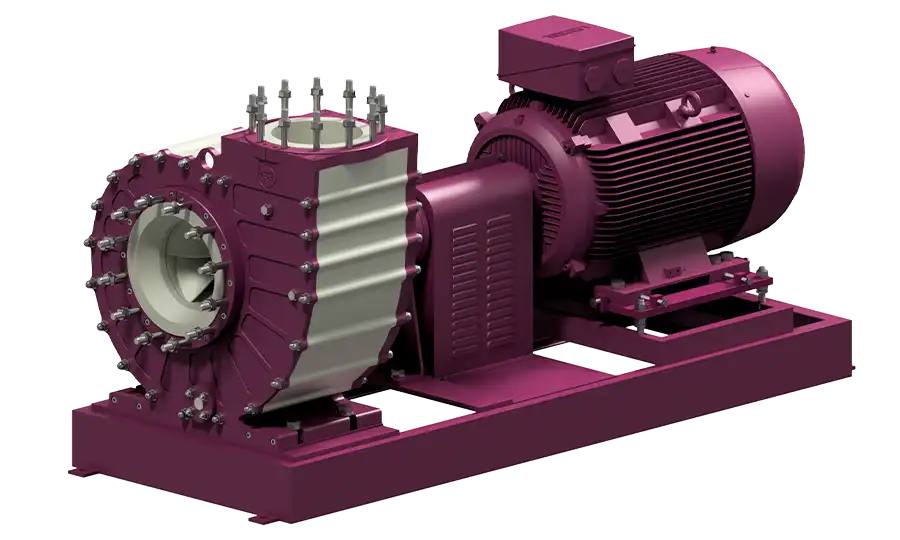

CGK

Horizontal centrifugal pumps with mechanical seal

LONG COUPLED

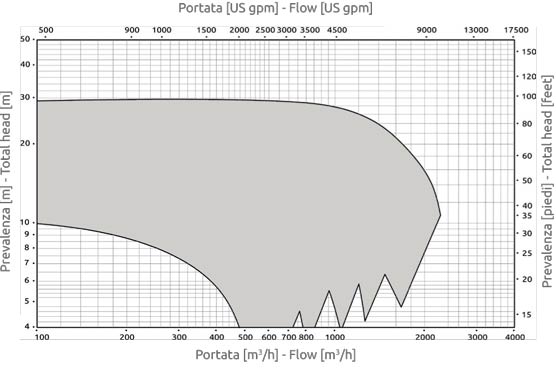

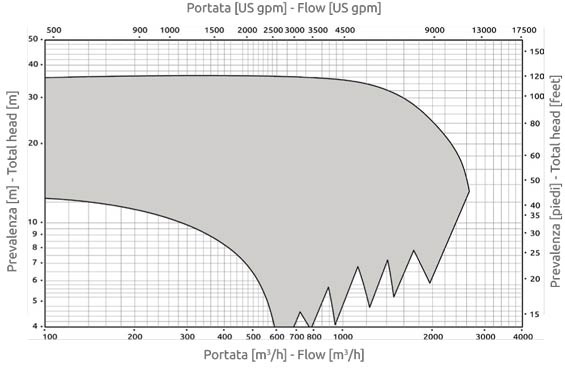

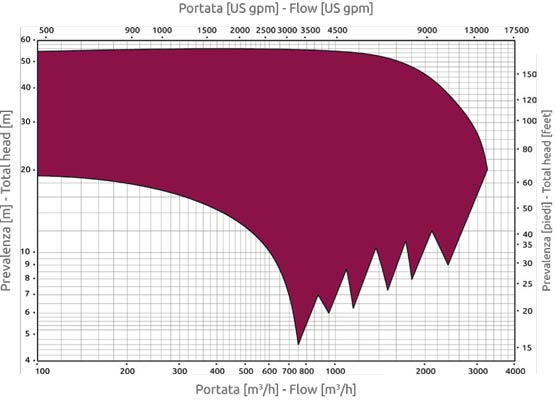

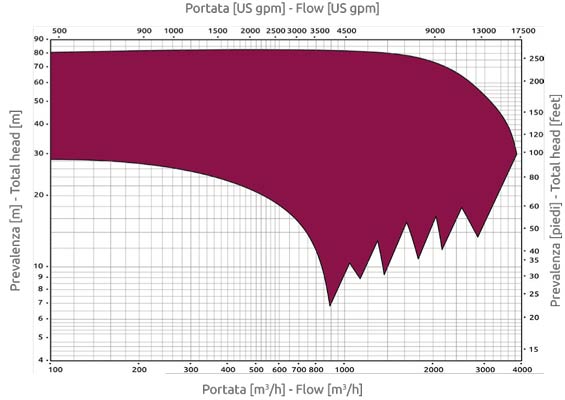

The new CGK pump is developed to handle corrosive liquids with flow rates from 200 m3/h to 4.000 m3/h. The low pressure from 2.5 mcl to 80 mcl and the close coupled availability identify this series as a unique product in thermoplastic range.

Features:

• High efficiency impeller & volute (82% ÷ 86% Best Efficiency Point)

• Semi-open or Closed impeller configuration

• Solids up to 10%

• Grease or Oil lubricated versions

• Impeller separated with shaft sleeve

• No screwing impeller

• Shaft Adjustment system

• Coupling & Close coupled versions

• Internal/External – Single/Double mechanical seal configuration

• PP, PVDF, PE-UHMW materials

Accessories

• Draining hole

• Residual fluid collection tank

• Pressurised tank for mechanical flushing

Download the catalog and the technical sheet complete with technical drawing with overall dimensions

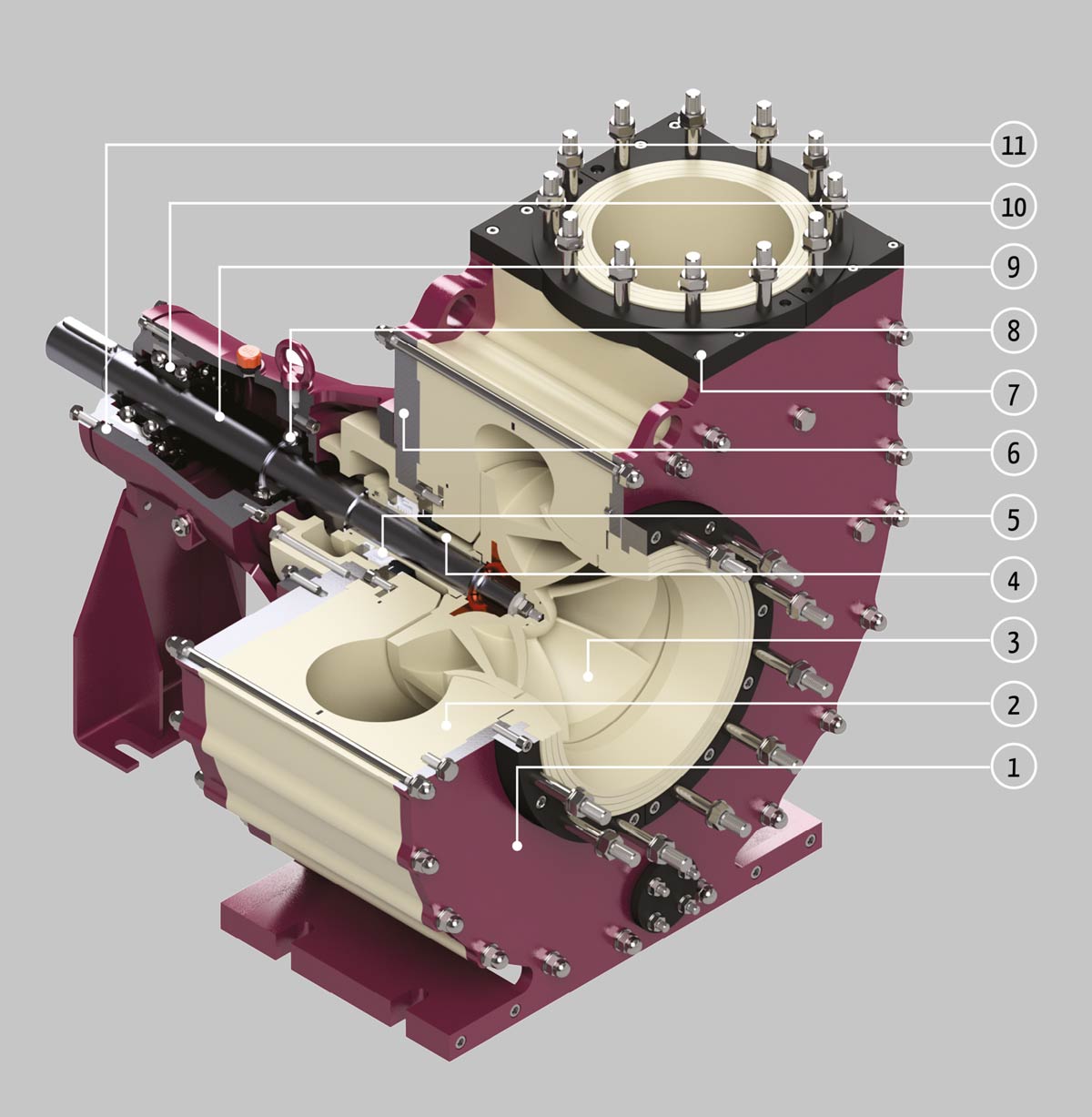

Main Components

Extra-thick front metal armour made of S235JR-EN1025 Carbon steel.

Casing made of extra-thick PP, PVDF or PE-UHMW manufactured using mechanical machining processes.

Centrifugal impeller made of PP, PVDF or PE-UHMW; semi-open model for particle-loaded fluids and closed for pumping high-temperature solutions. Axial selfbalancing guaranteed by rear counterblades; protected central metal insert.

Shaft sleeve in PP, PVDF or PE-UHMW. Fully covering the part of steel shaft in contact with the process liquid and manufactured as a one-piece component. It rotates integrally with the impeller but is independent from it.

Standardized mechanical seal, selected according to plant requirements and process requirements.

Extra-thick front metal armour made of S235JR-EN1025 Carbon steel.

Discharge flange constructed in two halves, made of S235JR-EN1025 Carbon steel.

Single row radial bearing.

Balanced shaft made of 42CrMo4 Carbon steel (with special alloy on demand), oversized to support torsional and radial forces. Precision machined from solid bar stock and protected by PP, PVDF or PE-UHMW shaft sleeve.

Rear double row, angular contact ball bearing, designed to withstand axial and radial hydraulic forces.

Bearing housing made in corrosion resistant cast iron G25.

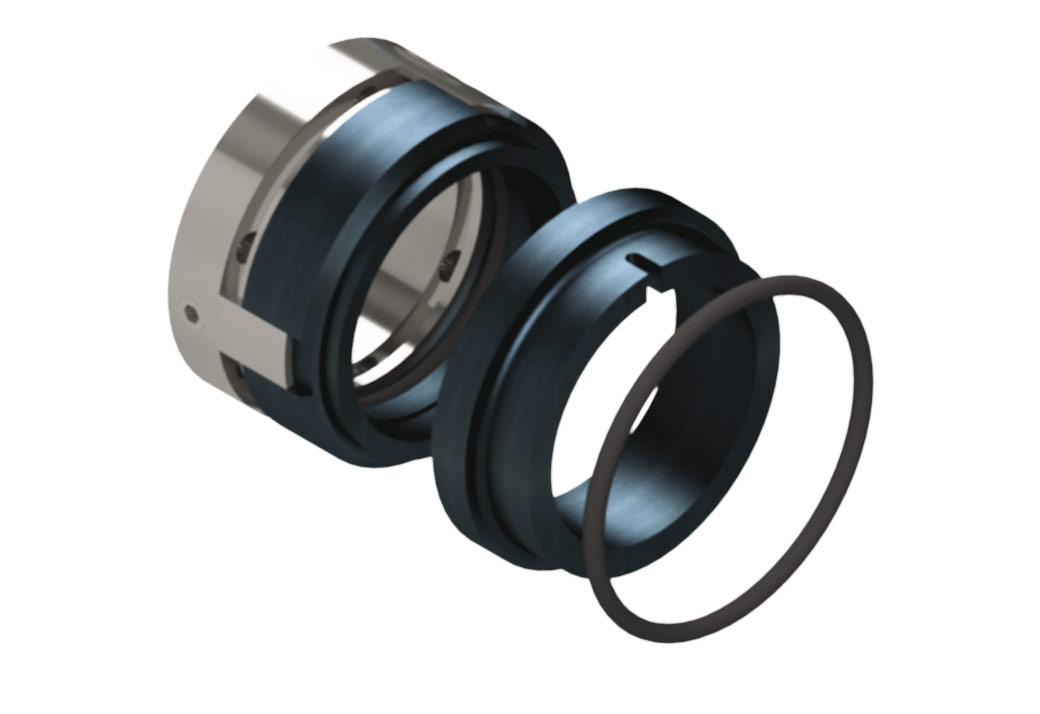

Mechanical seals

Elastomeric bellows seal

Mechanical seal for moderately corrosive, clean and not excessively hot liquids. Static and rotating rings in SiC, spring and armour in SS316 not in contact with the process liquid, elastomeric bellows in EPDM or FPM. Available in the external (B6E – B6EC), internal (B6I – B6IC – B6IH) and double-flushed (B6EDF – B6EDFC) types.

PTFE bellows seal

Mechanical seal for highly corrosive fluids and high temperatures. Static and rotating rings in three different combinations (SiC-SiC, SiC-Al2O3, Al2O3-PTFE-C), PTFE bellows, spring and armour in SS316 not in contact with the pumped liquid. Available in external (JRS – JRS1 – JRA) and double-flushed (JR2S – JR2S1 – JT2P – JR2A) types.

Seal with elastomeric O-ring

Mechanical seal for moderately corrosive, clean and not excessively hot liquids. Static and rotating rings in two different combinations (SiC-SiC, Carbon-graphite-SiC), spring and armour in Hastelloy C276, O-ring in EPDM o FPM. Available in the internal (UMG – UMS) and double-flushed (UM2G – UM2S) types.

application fields