Home » Horizontal centrifugal pumps » CFM-Q

CFM-Q

Horizontal fiberglass centrifugal pumps with mechanical seal

CLOSE COUPLED

CFM close coupled horizontal centrifugal pumps with ANSI/ASME B73.1 suction and discharge outlets, presents strong and resistant construction.

Material of Construction

Materials of construction are available for a wide corrosive liquids range and a long history of application experience. The flexibility through a wide range of materials selections for corrosive and abrasive liquids is a distinction of Affetti Pumps.

Accessories

• Draining hole

• Residual fluid collection tank

• Pressurised tank for mechanical flushing

• Self-priming tank

• Dry-run protector

RTM molding

The fiberglass components of the CFG and CFM pumps are obtained by RTM (RESIN TRANSFER MOULDING) using vinyl ester reinforced with long glass-fibers.

Download the catalog and the technical sheet complete with technical drawing with overall dimensions

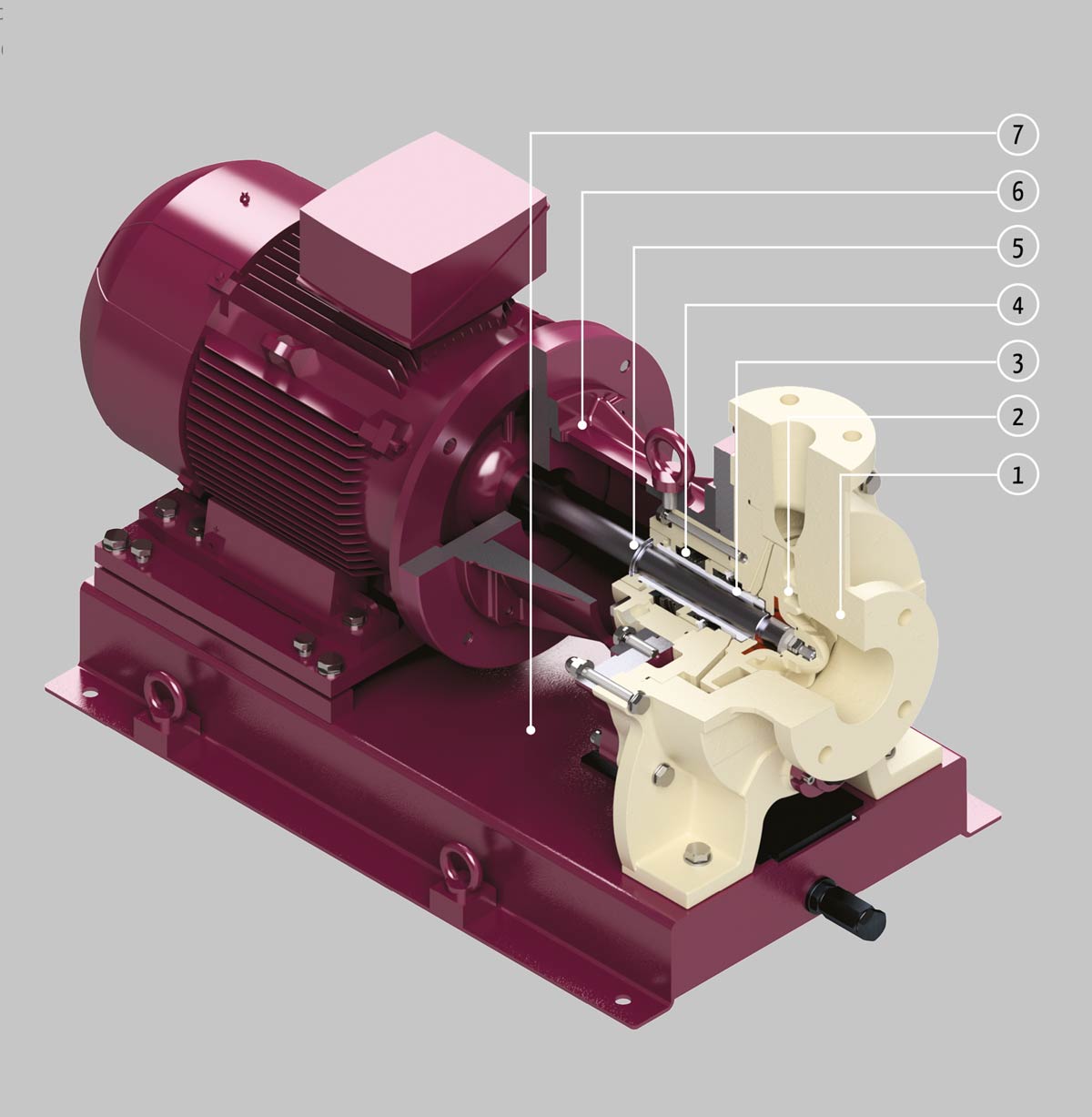

Main Components

Pump casing made in solid FRP with high thickness to ensure optimal mechanical strength and chemical resistance- without the need for metallic armoring.

Semi-open centrifugal impeller with rear back-vanes for axial self-balancing; with encapsulated metallic insert.

Shaft sleeve in FRP or PE-UHMW. Fully covering the part of steel shaft in contact with the process liquid and manufactured as a one-piece component.

It rotates integrally with the impeller but is independent from it.

Standardised mechanical seal. Different types are used depending on of the liquids pumped, the temperatures and the working hours endured by the machine.

Standardized mechanical Balanced shaft made of 42CrMo4 Carbon steel(with special alloy on demand), oversized to support torsional and radial forces.

Precision machined from solid bar stock and protected by FRP or PE-UHMW shaft sleeve. Single row radial bearing.

Cast iron intermediate adaptor. A unique piece designed to space electric motor from head pump.

Base plate in electro-welded S235JR-EN1025 carbon steel coated in a layer of epoxy primer and polyurethane primer.

System equipment for pump-motor axis regulation.

Mechanical seal

Elastometric bellows seal

Mechanical seal for moderately corrosive, clean and not excessively hot liquids. Static and rotating rings in SiC, spring and armour in SS316 not in contact with the process liquid, elastomeric bellows in EPDM or FPM. Available in the external (B6E – B6EC), internal (B6I – B6IC – B6IH) and double-flushed (B6EDF – B6EDFC) types.

PTFE bellows seal

Mechanical seal for highly corrosive fluids and high temperatures. Static and rotating rings in three different combinations (SiC-SiC, SiC-Al2O3, Al2O3-PTFE-C), PTFE bellows, spring and armour in SS316 not in contact with the pumped liquid. Available in external (JRS – JRS1 – JRA) and double-flushed (JR2S – JR2S1 – JT2P – JR2A) types.

Seal with metallic armour

Mechanical seal for moderately corrosive, clean and not excessively hot liquids. Static ring in Al2O3 and rotating ring in Carbon-graphite , spring and armour in SS316 , O-rings in EPDM o FPM and gaskets in PTFE. Available in the external (B8E) and double-flushed (B8EDF) types.

Seal with elastometric O-ring

Mechanical seal for moderately corrosive, clean and not excessively hot liquids. Static and rotating rings in two different combinations (SiC-SiC, Carbon-graphite-SiC), spring and armour in Hastelloy C276, O-ring in EPDM o FPM. Available in the internal (UMG – UMS) and double-flushed (UM2G – UM2S) types.

application fields