Volumetric self-priming pumps

The volumetric self-priming pump with elastic coupling, range VGA has been designed to load-unload basins, tank-trucks, tanks where is no possible the flooded installations. Reversible and easy to handle, the VGA pumps can prime from negative suction head of max 4 meters without the necessity to feel the priming chamber the first time.

Easy to handle, the pumps of this range have strong construction, produced in their components with high thickness to give a product with the maximum reliability. The electric motor is connected to the pump through elastic coupling with spacer, fixed on a carbon steel base plate.

Material of Construction

Suitable to transfer low viscosity acids and basic liquids, the internal part in contact with liquid are totally built in thermoplastic (PP-PVDF-PVC), the gaskets and the impeller blades are in a suitable material (EPDM). Standard are installed lip seals in EPDM or FPM.

Accessories

• Dry-run protector

• Reverser

• Suction and discharge flanges

• Suction filter

• Trolley

Download the catalog and the technical sheet complete with technical drawing with overall dimensions

* Fill the form to download

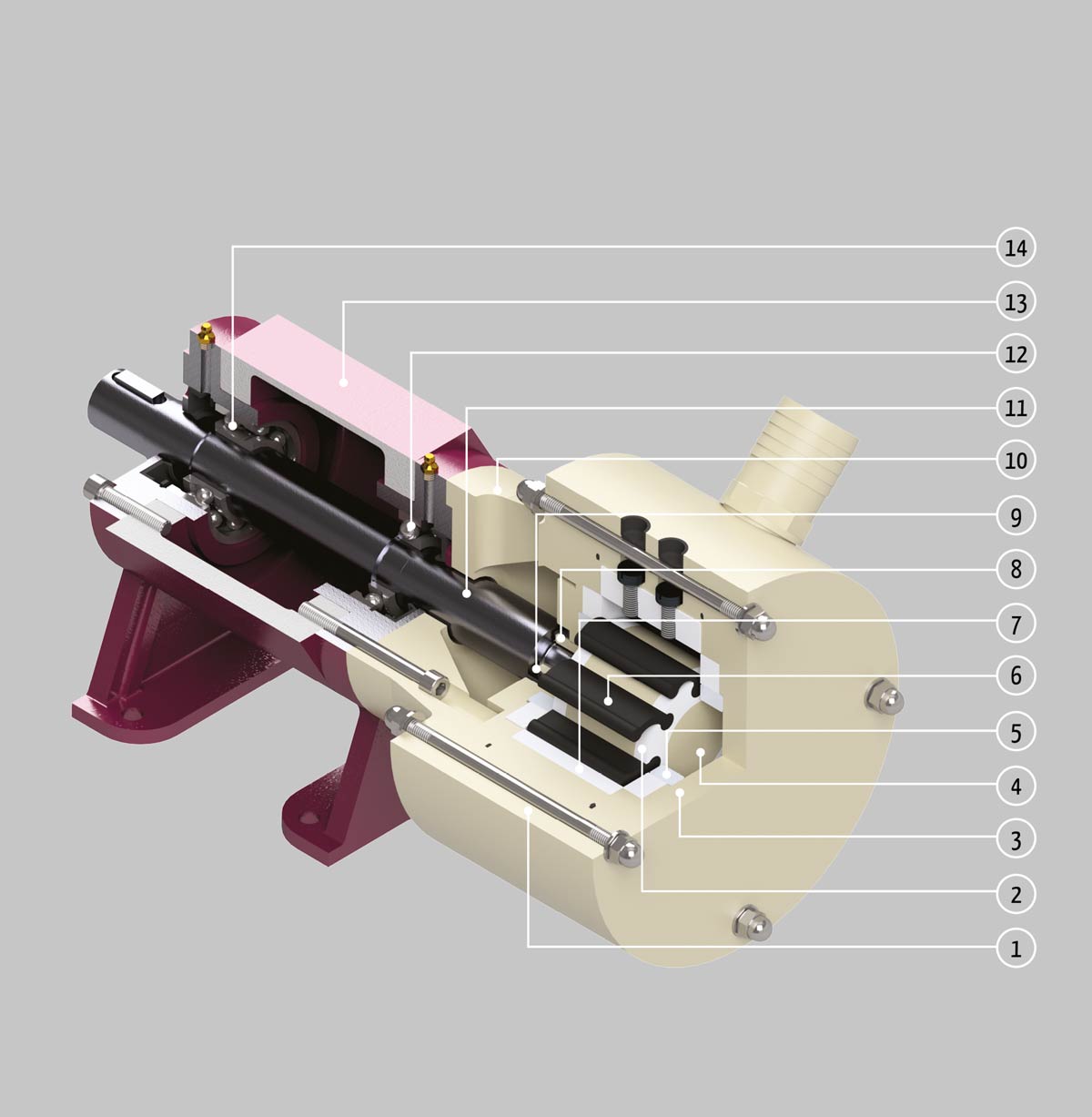

Main Components

- Casing made of extra-thick PP, PVDF or PVC, manufactured using mechanical machining processes.

- Rotor counter-face in PTFE, extractable from the hub.

- Casing cover made of PP, PVDF or PVC, seals the volute hermetically.

- Cylindrical rotor in PP, PVDF or PVC. Eight grooves house the flexible elastomer blades.

- Ground thrust washer in Al2O3, axially locates the rotor with flexible blades.

- Flexible rubber blades (EPDM) inserted into grooves on the rotor. Removable and independent from each other, can be replaced if worn or torn.

- Casing jacket in extra-thick PTFE, lining the volute.

- An Al2O3 bushing covers the area of the shaft in contact with the fluid and rotates integrally with the rotor.

- Rear seal ring, fitted in pairs and countered with a lip seal in EPDM or FPM.

- Intermediate adaptor of a strong design in thermoplastic material.

- Balanced shaft made of 42CrMo4 Carbon steel, structured to easily support torsional and radial forces. Mechanically machined exclusively from solid bar stock.

- Front rigid radial ball bearing, designed above all to resist radial loads during operation of the machine.

- The shaft support is a 3-piece construction in cast aluminium.

- Rear double row angular contact ball bearing, designed to withstand axial thrusts generated by the fluid during operation. Rigid radial ball bearings are fitted in this position for models equipped with size 71-80-90 motors.