Cantilever centrifugal sump pumps

The CGV-S range of cantilever pumps was designed to meet a demand for vertical pumps that could operate without any risk of damage to the shaft guide bushings from abrasive solid particles contained in the fluid or from dry running, such that the design does not foresee any guide mechanisms close to the impeller. The carbon steel 42CrMo4 pump shaft coated in corrosion-proof plastic, assembled in a cantilever manner and guided by strong bearings housed in the cast iron intermediate adaptor, is connected to the motor with an elastic coupling.

Material of Construction

All parts in contact with the fluid pumped are made of thermoplastic material (PP-PVDF-PEHD); column length available ranges from 500 to 1500 mm.

Accessories

• Flanged connection on discharge line

• Motor rain guard

• Filter on suction line

• Extension pipe on suction line

Download the catalog and the technical sheet complete with technical drawing with overall dimensions

* Fill the form to download

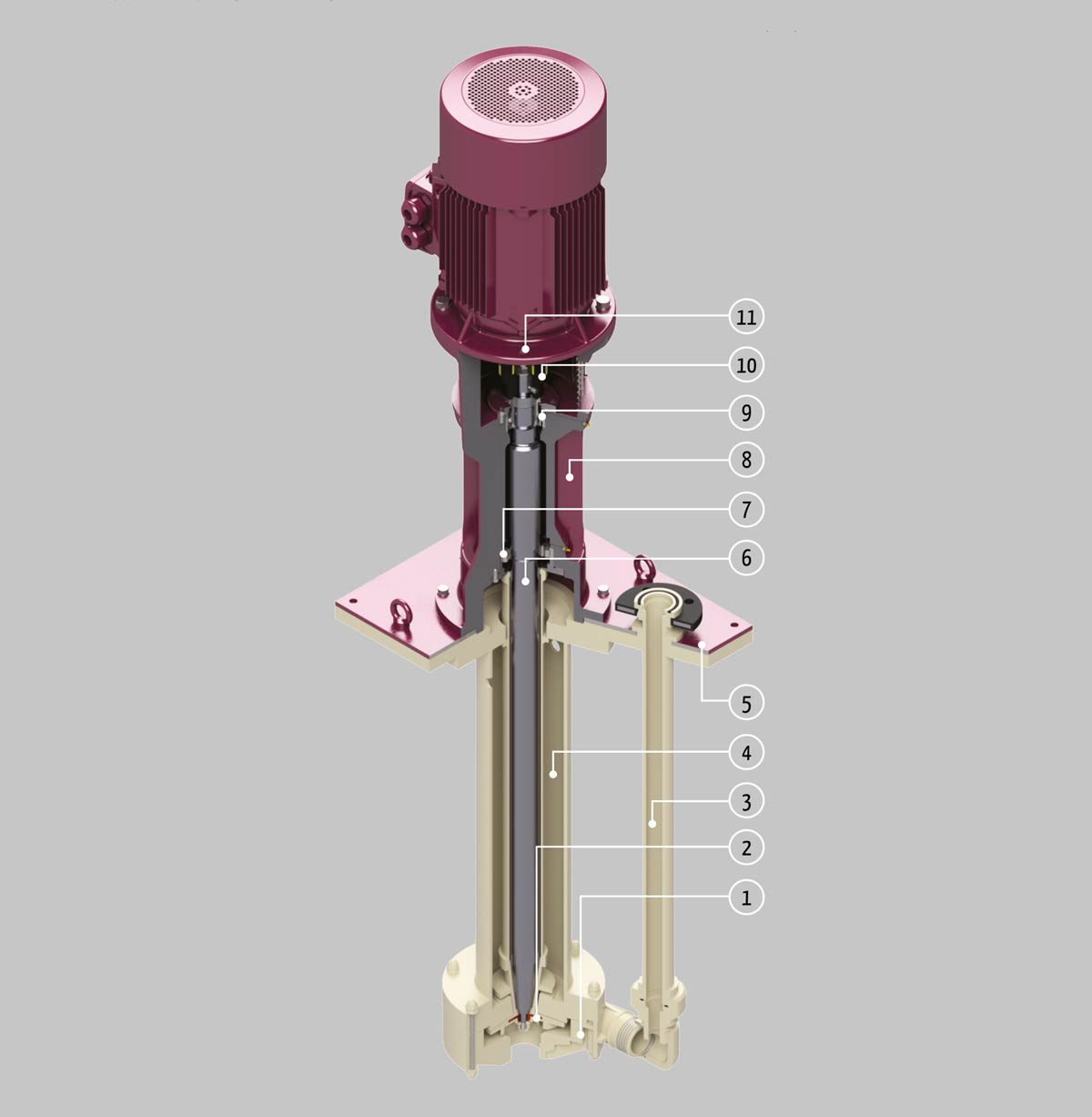

Main Components

- Pump casing made of extra-thick PP, PVDF or PE-UHMW, manufactured using mechanical machining processes. For pump models 32-125, 40-130, 40-160 and 50-160, the part is injection moulded and is only available in PP or PVDF.

- Centrifugal impeller in PP, PVDF or PE-UHMW (the part is only available in PP or PVDF for pump models 32-125, 40-130, 40-160 and 50-160); semi-open version for particle-loaded fluids or closed for pumping solutions at high temperatures. Axial self-balancing guaranteed by rear counterblades; protected central metal insert.

- Thermoplastic discharge pipe.

- Column manufactured entirely from thermoplastic material.

- Extra-thick PP plate reinforced with a sheet of steel.

- Balanced shaft made of 42CrMo4 carbon steel, structured to easily support torsional and radial forces. Made exclusively from solid bar stock using mechanical machining processes and fully coated in thermoplastic material.

- Roller bearing to withstand radial thrusts.

- Intermediate adaptor in cast iron contains the bearings and the elastic coupling and distances the motor from the rest of the pump.

- Ball bearing to guide the shaft and withstand thrusts generated by the impeller.

- Elastic coupling fitted to absorb any axial misalignment and allow the motor to be disassembled without having to remove the pump.

- Three-phase asynchronous electric motor, in compliance with IEC (NEMA available on request).