Centrifugal pumps with magnetic drive

The centrifugal monobloc magnetic drive pump, range MMB-L, has been designed to solve the different problems generated sometimes from the leakage through the mechanical seals, with the consequence to cause serious environmental contaminations. The impeller rotation is possible thanks to a movement transmitted from the coupling through magnetical induction.

Easy to handle, the pumps of this range are strong, compact construction, produced in their components with high thickness to give a product with the maximum reliability.

Material of Construction

Suitable to transfer acid and basic solutions, the wet ends, tare produced in thermoplastics (PP-PVDF) and O-ring in the proper elastomer material (EPDM-FPM-FEP-FFKM). The impellers installed are generally semi-open, but they are available in the closed version for hot liquids and without solids in suspension. Optionally available the dry-running protector.

Accessories

• Draining hole

• Self-priming tank

• Dry-run protector

• Trolley

Download the catalog and the technical sheet complete with technical drawing with overall dimensions

* Fill the form to download

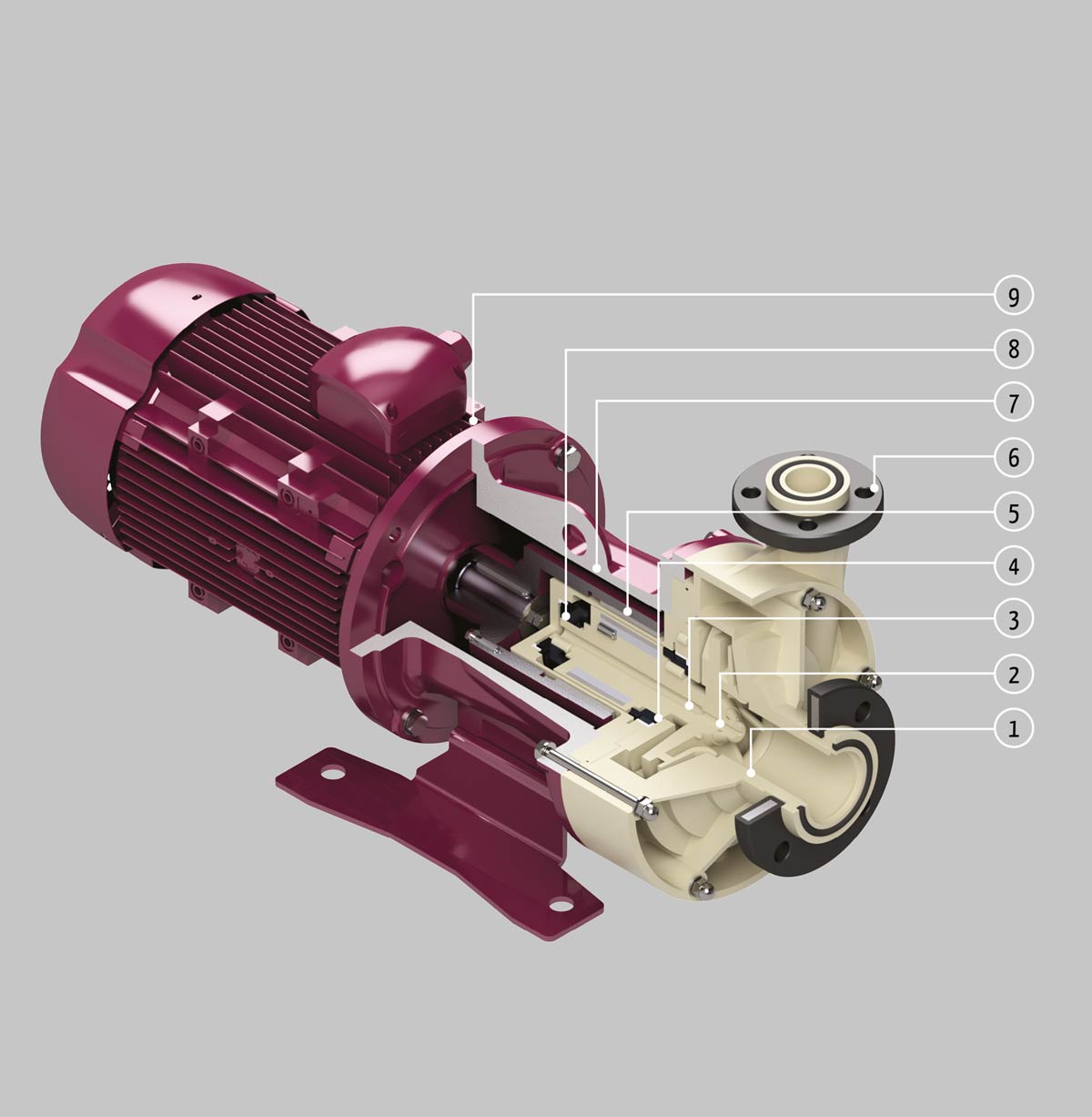

Main Components

- Casing made of extra-thick PP or PVDF, manufactured using mechanical machining processes for 65-125 and 65-160. For pump models 25-125, 32-125, 40-130, 40-160 and 50-160, the part is injection moulded.

- Centrifugal impeller made of PP or PVDF; semi-open model for particle-loaded fluids and closed for pumping high-temperature solutions. Axial self-balancing guaranteed by rear counter-blades.

- Rotor in PP or PVDF with a central hole for lubricating the rear guide bushings and impeller balancing. The internal magnetic core, composed of a carbon steel support and magnetic bars in Nd-Fe-B, is fully encapsulated in thermoplastic material to protect it from the rotor.

- Revolving guide bushings in PTFE CG (SiC available on request), rotate integrally with the rotor.

- External magnetic core with magnetic bars in Nd-Fe-B rotating integrally with the motor, transmits the movement to the rotor.

- Loose flanges in glass-reinforced PP, strengthened internally with a steel core.

- Intermediate adaptor in aluminium equipped with support feet in Carbon steel

- Static guide bushings in SiC (Al2O3 available on request).

- Three-phase asynchronous electric motor, in compliance with IEC (NEMA available on request).